Calgary’s Leading Fabrication Shop for Oilfield Truck Service Bodies

GET A QUOTE FOR YOUR project

GET A QUOTE ›

HOW WE BUILD YOUR OILFIELD TRUCK SERVICE BODY

SEE how we do it ›

SEE OILFIELD TRUCKS WE'VE BUILT

SEE PROJECT GALLERY ›

What to expect when we fabricate a custom service body for your oilfield truck

Initial

Consultation

We meet with you to discuss your truck chassis and the equipment you carry. We also review the conditions where you operate, from winter drilling sites to remote oil leases.

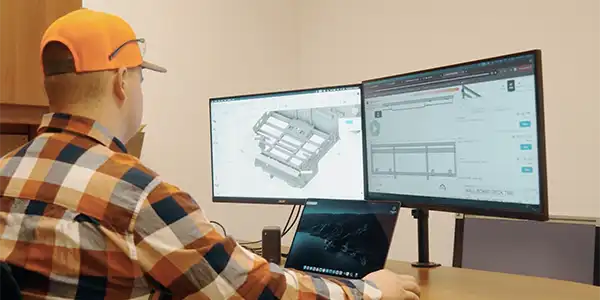

DESIGN PROCESS

Our drafting team creates a detailed layout accounting for proper weight distribution and necessary compartments or flooring. We also factor in space for cranes, reels, or generators.

PRECISION FABRICATIONS

Our team of Red Seal welders fabricate the body. We integrate design features like compartments and reinforced mounting points for field equipment.

FINAL INSPECTION & DELIVERY

Each service body is painted or powder coated. Then we wire it with work lighting and test fit it to your truck chassis. Your truck will be ready to go to the field when you pick it up.

If you have any questions or need help, feel free to contact our team, or you can call us any time (403) 998-5169

ABOUT US

Serving North America’s oilfield operators

Projects

Clients

Trusted by businesses across Canada and the northern U.S. for reliable builds.

Rose Gentles

Great business to work with. They dealt with modifications on the fly and worked with me to make sure my requirements were met. They did a beautiful job, couldn’t be happier. Tell them what you need and let them do what they do best. You won’t be disappointed!

See more reviews

GALLERY

OILFIELD TRUCK GALLERY

FIELD SERVICE UNITS

PICKER & CRANE SERVICE TRUCKS

FLEET BUILD FOR OILFIELD CONTRACTORS

WE ARE ALWAYS READY TO HELP YOU

MORE INFORMATION

OILFIELD TRUCK SERVICE BODIES FAQS

How do you make sure oilfield service bodies can handle heavy equipment?

Service bodies for oilfield trucks must weather demanding environments and stand up to heavy use for years. We reinforce the subframe, floors and mounting points. This allows your service body to carry welders, compressors, cranes and reels safely over rough terrain.

What materials do you use for oilfield applications?

We typically build in heavy duty high tensile or stainless steel for maximum strength and corrosion resistance. Powder coated finishes can also be used for added durability.

Can you integrate power systems and lighting?

Yes. We can add generator mounts and inverter systems to your design. We can also add work lighting, beacons and compartment lights so your crew can work safely day or night.

Do you weatherproof oilfield service bodies?

Yes. We use industrial grade seals and tight fitting doors to keep out environmental hazards like snow or mud.

Can you design for extreme weather and remote work conditions?

We always build for the realities of the oilfield. From the oilsands of Alberta to the Bakken field in North Dakota, these are some of the harshest industrial environments in North America, and our service bodies are engineered for extreme conditions. We can install insulated compartments for cold weather operations, ruggedized components for long distance travel, and more.

Can you integrate cranes or picker systems into the body?

Yes. We reinforce the mounting areas and install outrigger pads so your lifting equipment is stable and safe to operate.

Do you offer fleet wide builds for oilfield companies?

Yes. We can produce multiple matching units so your crews have consistent layouts and equipment placement across all trucks.

What is the turnaround time for an oilfield service body?

Most oilfield builds are completed in 4 to 6 weeks. More complex builds with multiple integrated systems may take slightly longer. We provide regular progress updates throughout the project.