Get Custom Wallboard Truck Decks from Calgary’s Leading Fabrication Shop

GET A QUOTE FOR YOUR project

GET A QUOTE ›

how we deck out your WALLBOARD truck

SEE how we do it ›

see WALLBOARD trucks we've done

SEE PROJECT GALLERY ›

What to expect when we fabricate a custom deck for your wallboard truck

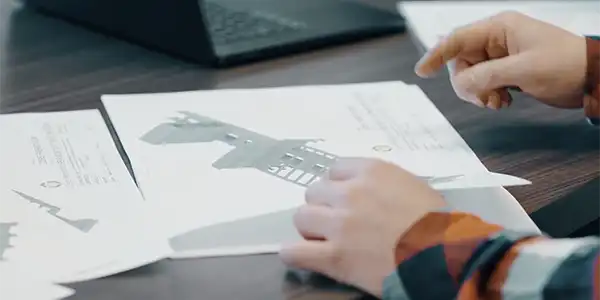

Initial

Consultation

We meet with you to review your chassis specs, wallboard sizes and typical jobsite requirements.

DESIGN PROCESS

Our drafting team creates a reinforced deck layout with optimal tie down placement and forklift accessibility for loading and unloading.

PRECISION FABRICATIONS

CWB certified welders build your deck using heavy duty materials designed to support the goods you transport, then finish it for long term durability.

FINAL INSPECTION & DELIVERY

Your deck is weighed, certified and fully compliant with National Safety Mark requirements before you pick it up, so it’s ready to hit the road right away.

If you have any questions or need help, feel free to contact our team, or you can call us any time (403) 998-5169

ABOUT US

Serving customers across North America

Projects

Clients

Trusted by businesses across Canada and the northern U.S. for reliable builds.

Rose Gentles

Great business to work with. They dealt with modifications on the fly and worked with me to make sure my requirements were met. They did a beautiful job, couldn’t be happier. Tell them what you need and let them do what they do best. You won’t be disappointed!

See more reviews

GALLERY

roofing truck GALLERY

DRYWALL SUPPLY FLEETS

CONSTRUCTION MATERIAL HAULERS

ROOFING & RENOVATION SUPPLIERS

WE ARE ALWAYS READY TO HELP YOU

MORE INFORMATION

WALLBOARD Truck Deck FAQs

How do you make sure the deck can handle the weight of a full drywall load?

We start by calculating the total weight of the wallboard you typically carry, then engineer the deck and frame supports to exceed that capacity. Every deck is weighed and certified after fabrication to ensure compliance with CMVSS standards and safe axle loading.

What materials do you recommend for a wallboard deck?

Most operators want heavy duty steel framing with a hardwood or steel deck surface. We can also add options to protect against inclement weather and jobsite debris that can damage unprotected wood. Corrosion resistant coatings and powder coated finishes are popular options for this.

Can you add integrated storage or tie down systems?

Yes. We can install E track systems, custom tie down points, built in toolboxes and even slide out drawers. These features make it faster and safer for your crew to secure loads and access tools.

How do you prevent deck warping, rust, or mold over time?

We seal and finish decks for weather resistance, design proper drainage to prevent standing water and use materials that resist rot and corrosion. Powder coated steel and treated hardwood options are available for long term durability.

Can you build in access points for my truck’s frame or onboard equipment?

Absolutely. We can include cutouts or removable panels for easy access to the truck frame, fuel tanks, or generators, ensuring maintenance can still be performed without deck removal.

What mounting methods do you use for stability?

We design and fabricate custom brackets, supports and in some cases polyurethane mounting pads to distribute weight evenly and reduce vibration. Mounting is welded or bolted in house by CWB certified welders for strength and reliability.

Can you add safety features like headache racks or gates?

Yes. We can integrate headache racks to protect the cab and provide accessory mounting points, as well as custom gates or tailboards to keep sheet goods secure during transport.

How long does it take to build and install a wallboard deck?

Many smaller builds are completed in 2 to 4 weeks. Larger projects with custom features or multiple trucks may take up to 6 weeks. We provide a clear schedule and progress updates so you can plan your deliveries without unexpected downtime.

Can I visit your facility to see the build in progress?

We encourage scheduled visits so you can see our vertically integrated process firsthand. From raw steel to paint, every step of the build happens under one roof at our Calgary facility.

Do you ship outside Alberta?

Yes. We serve customers across Western and Eastern Canada, as well as the northern United States. Logistics support can be arranged for delivery outside the Calgary area.